Leading the Future of the Industry with "Green Innovation" - Successful Conclusion of the VOCs Waste Gas Purification and Recovery Project Review Meeting for Dry Production Lines

Release time:

2025-04-14 15:38

Source:

On April 10, 2025, Fujian Huaxia Synthetic Leather Co., Ltd. welcomed a significant moment in Long'an Development Zone, Fuding City—the acceptance review meeting for the "VOCs Waste Gas Purification and Recovery Project for Dry Production Line" was successfully held.

The implementation of this project marks a solid step forward for the company in the fields of environmental protection technology innovation and sustainable development, and also provides a benchmark demonstration for the green transformation of the synthetic leather industry.

Environmental Protection First; Twenty Years of Green Cultivation

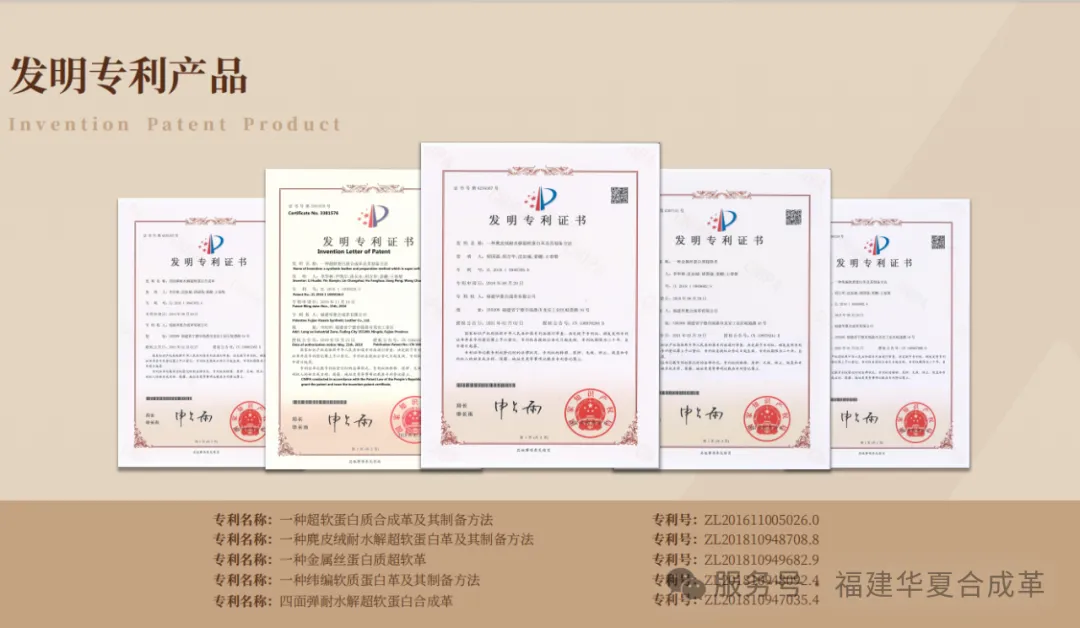

As a leading enterprise in China's synthetic leather industry, Fujian Huaxia Synthetic Leather, since its establishment in 2005, has always regarded environmental protection as its lifeline. As early as 2009, the company invested more than one million yuan to initiate clean production transformation, becoming the first enterprise in eastern Fujian to independently promote clean production, and has passed international certifications such as GRS (Global Recycled Standard) and OEKO-TEX (Ecological Textile Product Certification). In recent years, the company has developed water-based leather, recycled leather, and bio-based leather among other innovative products. Water-based leather products, because they do not contain toxic solvents such as DMF, are widely used in infant products and medical health fields, with enthusiastic market response.

VOCs Waste Gas Purification and Recovery: Technological Breakthrough and Industrial Value

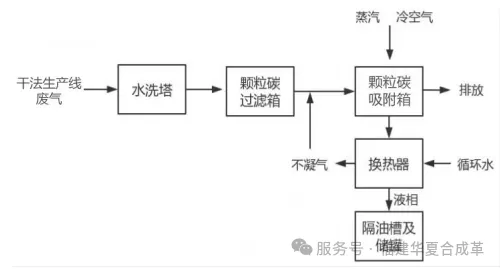

The acceptance of the Dry Production Line VOCs Waste Gas Purification and Recovery Project represents another significant measure by the company in waste gas treatment. By adopting adsorption-condensation recovery technology, combined with an intelligent control system, the project can efficiently capture and recover VOCs (volatile organic compounds) produced during the production process, with a pollutant removal rate exceeding 85%. This technology not only significantly reduces the impact on the atmospheric environment but also achieves resource recycling, saving the company hundreds of thousands of yuan in hazardous waste treatment costs annually.

Green Innovation Matrix: Comprehensive Innovation from Technology to Products

Huaxia Synthetic Leather's environmental protection practices go far beyond this:

1. Recycled Leather Using post-consumer recycled polyester as the base fabric, combined with a water-based PU surface layer, to create traceable recycled material products, GRS certified, promoting "zero petroleum-based" production.

2. Protein Breathable Leather Mimicking the structure of real leather using biomimetic technology, with breathability and softness comparable to natural leather, widely used in high-end clothing and automotive interiors, reducing reliance on animal leather.

3. Bio-based Leather Using plant fibers as raw materials, certified by the US Department of Agriculture USDA Biobased, helping to reduce carbon footprint by more than 30%, and selected for Ningde City's "Green Manufacturing Demonstration Project".

Industry Leadership: Standard Development and Ecological Construction

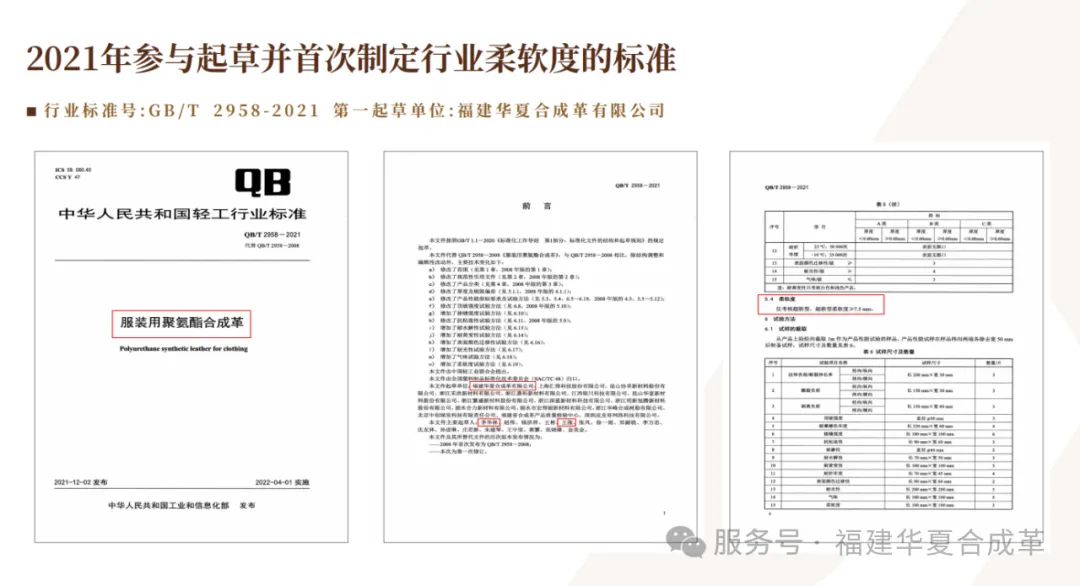

As an industry benchmark, Huaxia Synthetic Leather actively participates in standard setting, leading the drafting of 21 group standards, including the "General Rules for the Evaluation of Green Parks for Artificial and Synthetic Leather," promoting the transformation of the Fuding synthetic leather industrial cluster towards cleanliness and low carbon. At the same time, the company, in collaboration with the government, has built a park-level central heating, wastewater treatment, and solid waste treatment center, achieving full-process control of "three wastes," contributing to Fuding being rated as "China's Ecological Synthetic Leather Industrial Park".

Future Outlook: Continuous Exploration under the Carbon Neutral Goal

"Environmental protection is not a cost, but a competitiveness." Huaxia Synthetic Leather General Manager Li Hualin emphasized. In the future, the company has already begun to further expand into graphene leather, solvent-free leather, and other cutting-edge fields, and explores carbon capture and green electricity applications, striving to achieve full value chain carbon neutrality by 2030.

The acceptance of this VOCs waste gas purification and recovery project is not only a milestone in technological achievements but also a vivid footnote to the company's practice of the "革故鼎新、绿色共生" philosophy. Under the guidance of the "dual carbon" goals, Fujian Huaxia Synthetic Leather is using innovation as its pen to write the green future of the synthetic leather industry!